Comprehending the Relevance of Membrane Switches in Customer User Interfaces

Membrane buttons are essential parts in the design of reliable interface, promoting not just performance yet additionally boosting aesthetic appeal and customer communication. Their one-of-a-kind features, such as resistance to customizable layouts and environmental factors, make them suitable for a diverse array of applications throughout multiple industries. As we explore the various benefits and future trends associated with Membrane modern technology, it becomes clear that these switches are greater than just elements; they represent a merging of technology and practicality. The effects of this technology on customer experience deserve analyzing better.

What Are Membrane Buttons?

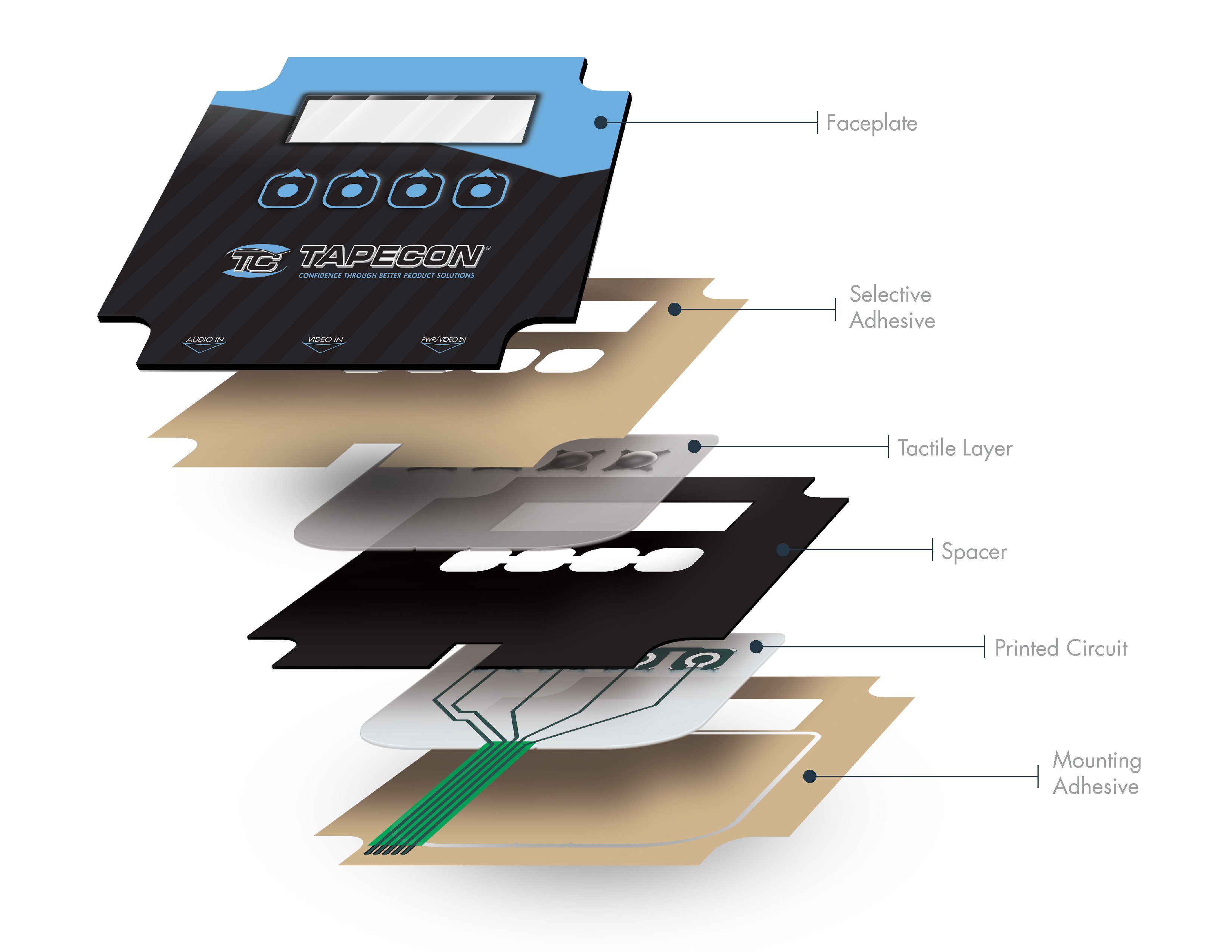

The spacer layer, which has adhesive residential or commercial properties, permits the separation of the circuit layer from the overlay, guaranteeing that the button continues to be in a non-activated state until pressed. When pressure is related to the overlay, it compresses the spacer layer, connecting the void and finishing the circuit in the underlying layer. This style not only reduces the physical space needed for traditional mechanical switches but likewise boosts the durability of the tool, as Membrane switches are generally resistant to dust, moisture, and other ecological variables.

Generally discovered in applications varying from customer electronic devices to clinical tools, Membrane switches are indispensable to contemporary innovation, providing a user-friendly and reliable user interface that aligns with contemporary design needs.

Benefits of Membrane Switches

While numerous button technologies exist, Membrane Switches deal distinct benefits that make them specifically preferable in numerous applications. Among the key advantages of Membrane switches is their small design, which enables space-saving applications in devices where genuine estate is limited. Their thin profile not just boosts visual allure however additionally helps with lightweight building and construction.

Another significant advantage is their resistance to environmental aspects. Membrane switches are commonly secured versus dampness, dirt, and pollutants, making them perfect for use sought after environments, such as medical gadgets and industrial tools. This toughness expands the life-span of the button, decreasing maintenance costs and boosting reliability.

Furthermore, Membrane buttons can be personalized to fulfill certain design requirements, including distinct graphics and shades that boost customer communication. Their responsive comments alternatives can additionally be customized to offer a satisfying individual experience. In addition, Membrane switches are cost-effective, especially in high-volume applications, as they can be created efficiently.

Applications in Different Industries

In the customer electronics market, Membrane switches prevail in tools such as microwaves, cleaning devices, and push-button controls. Their tactile responses and visual options boost individual experience while giving a smooth, modern-day appearance. Additionally, auto manufacturers use Membrane switches in dashboard controls and infotainment systems, where room is limited, and user interaction is essential.

Furthermore, the Check Out Your URL industrial field leverages Membrane buttons in control panels for equipment and devices, allowing for user-friendly operation in commonly severe environments. Their resistance to chemicals and wetness makes certain longevity and reliability in these applications. On the whole, the versatility of Membrane Switches contributes significantly to their extensive use, making them important in numerous technological domain names.

Style Considerations for Membrane Switches

When making Membrane buttons, a number of crucial factors to consider must be thought about to guarantee optimum functionality and customer experience. Firstly, the option of products is vital; picking durable, top notch substrates can improve the button's long life and resistance to environmental aspects such as dampness and temperature fluctuations.

Secondly, the style of the graphic overlay must focus on quality and convenience of usage. Symbols and message have to be legible, and the layout ought to help with user-friendly interaction (membrane switches). Furthermore, tactile feedback is vital; integrating a tactile dome or other mechanisms can enhance the user experience by providing physical verification of activation

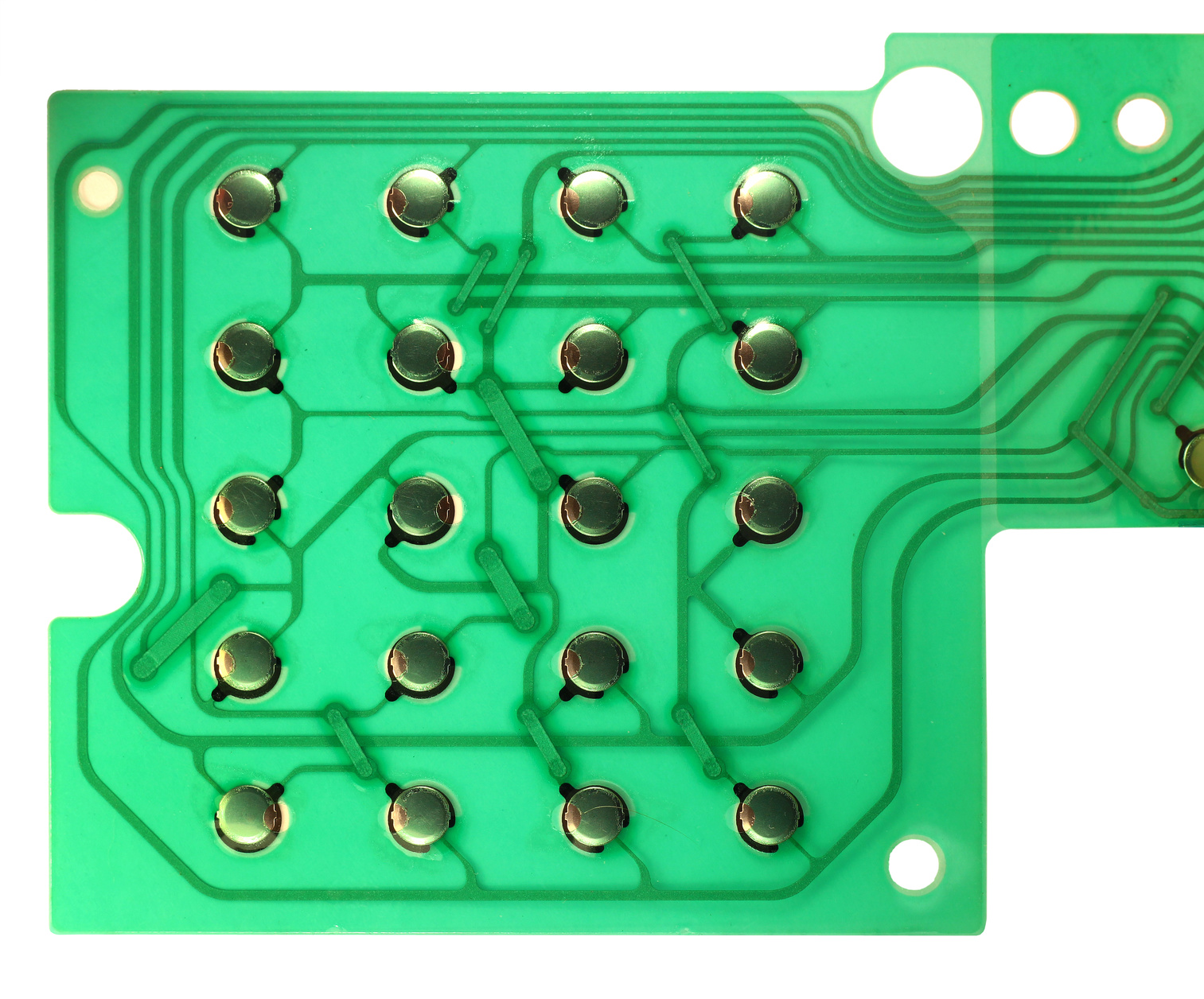

An additional vital variable is the button's electrical performance. Designers have to make certain that the conductive traces are effectively made to lessen resistance and prevent signal interference. This involves analyzing the called for actuation force and making certain compatibility with the digital parts they will certainly user interface with.

Future Patterns in Membrane Modern Technology

As innovation proceeds to advance, Membrane switches are positioned to advance considerably, driven by advancements in products and manufacturing techniques. One emerging pattern is the unification of advanced materials, such as adaptable substratums and conductive inks, which boost durability and decrease the general weight of Membrane switches. These materials not just enhance the responsive action yet additionally permit the design of switches that can withstand harsher environmental conditions.

Furthermore, the integration of touch-sensitive technologies is transforming traditional Membrane Switches right into even more interactive individual interfaces. Capacitive touch sensing units embedded within Membrane switch panels can provide an extra receptive and instinctive individual experience, aligning with the growing need for streamlined, contemporary styles in consumer electronics.

In addition, innovations in printing methods, such as digital and 3D printing, enable quick prototyping and modification of Membrane switches. This adaptability permits makers to respond more promptly to market demands and consumer choices.

Finally, sustainability is becoming a substantial emphasis, with producers discovering green materials and procedures. As these patterns unfold, the future of Membrane innovation promises enhanced capability, aesthetic allure, and environmental responsibility, solidifying their role in advanced individual interfaces across various markets.

Conclusion

In verdict, Membrane Switches stand for a vital component in the style of individual interfaces, incorporating capability with visual adaptability. As advancements in technology continue, the development of Membrane switches is expected to further refine user interfaces, driving development and improving usability in an increasingly complex technological landscape.

Membrane buttons are indispensable parts in the layout of reliable individual interfaces, assisting in not only performance but also boosting visual charm and user communication.Membrane Switches offer as an essential part in different individual interfaces, helping with a seamless communication in between individuals and digital tools.While many switch technologies exist, Membrane Switches offer distinctive benefits that make them especially desirable in numerous applications.Additionally, Membrane buttons can be personalized to meet specific layout demands, incorporating one-of-a-kind graphics and colors that enhance customer interaction.In verdict, over at this website Membrane Switches represent an essential element in the design of customer interfaces, combining capability with aesthetic adaptability.

Comments on “Ensuring Quality and Longevity with Membrane Switches in Electronics”